Gas flows horizontally through the scrubber. Scrubbing liquid is pumped from the bottom tank and distributed to the top of the packing zone.Liquid flows downward through the internal packing layer, increasing the gas-liquid contact area via the packing structure to enhance absorption efficiency.Demisters are located between treatment stages and at the outlet to effectively intercept droplet carryover.

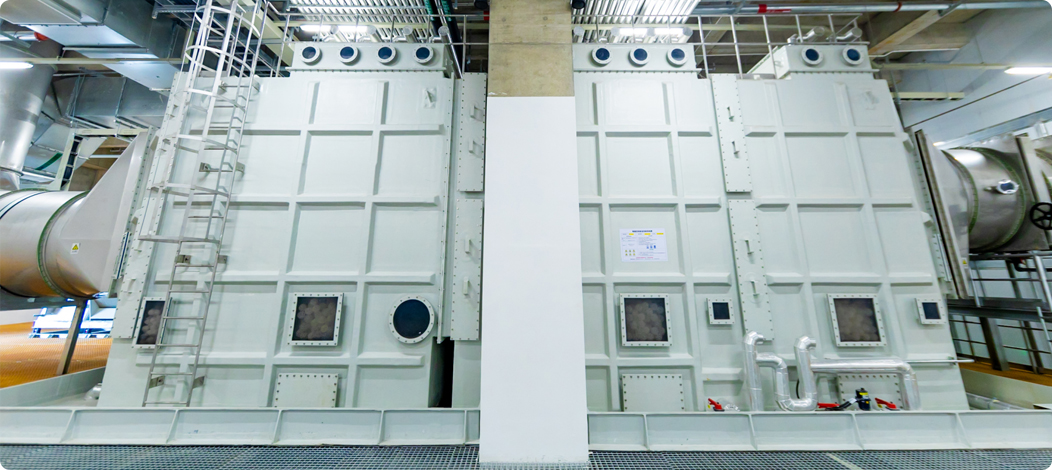

Client Need: Indoor multi-stage treatment equipment for efficiently treating exhaust gases in acidic process exhaust, utilizing indoor space fully, providing redundant capacity for full production. Exhaust medium reference: HCl, HF, H2SO4.

Solution: Horizontal three-stage scrubber system, single unit air volume approx. 110,000 m³/h. Multi-stage design with independent recirculating water systems for each stage, allowing independent sensor parameter setting. Components like tower body, tank, and spray system are designed for on-site assembly, facilitating hoisting and indoor placement.